Production

Each stage of production - from the poultry feed to the release of a finished product that will enter the kitchens of millions of families - is strictly subordinated to a single system, which ensures control of safety and stable quality.

Vertical integration at Poultry Production “Severnaya" includes 6 main business units.

The mixing of ingredients, granulation and storage of feed for the parent livestock and broiler sites is carried out at our own feed mill. Grain is supplied by both rail and water transport. All incoming raw materials undergo regulated internal quality control by sampling from each batch. The monthly production capacity is 40 thousand tons of feed.

The raising of broiler chickens begins with the production of the hatching eggs. The poultry parent stock is located at the “Poultry Parent Stock Production Woyskovitsy". The main task of the breeding site is to grow a healthy parent stock, maintain natural for the birds conditions and the primary quality control of hatching eggs.

Breeders produce about 2 million hatching eggs per week.

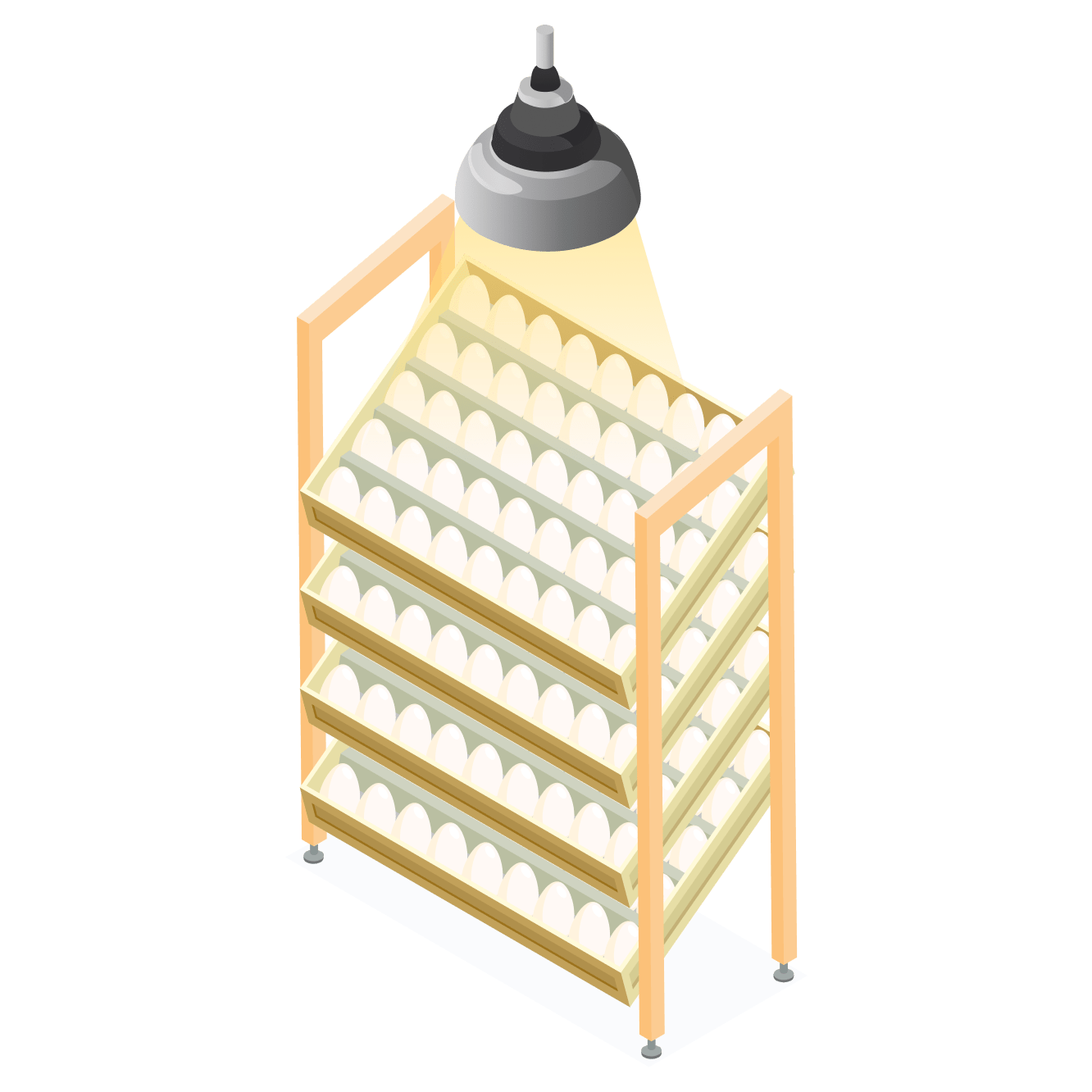

The hatchery located at "Severnaya" production site is one of the largest in Europe. In the hatchery, an additional quality check of the incoming hatching eggs is performed. In this division special attention is paid to creating optimal conditions for hatching, maintaining the environment and monitoring the health of day-old chicks.

Careful transportation of day-old broiler chicks from the hatchery to the poultry houses is carried out by a specialized transport, where special parameters of temperature, humidity and content of СО2 are also maintained.

Every week, about 2.5 million eggs are laid in setters. The hatching period is 21 days.

More than 300 poultry houses are located at 3 broiler sites in the Leningrad region. The poultry houses are equipped with automated systems for microclimate maintaining, feed supply and drinking water, that guarantee the birds are provided with close to natural living conditions.

All houses contain about 16 million broiler chickens at any one time.

On the day 45-46, the poultry is transported to the processing shop, where they are slaughtered, cut up, and the finished products are packed, chilled or frozen.

The cut up and packaging units are equipped with modern equipment from Europe, strictly observing the regulations on sanitary and hygienic requirements and the temperature regime of no more than +6°C.

Every shift on the production lines Products quality is monitored by state veterinary doctors.

One of the priority Poultry Production "Severnaya" tasks, as a food production, is a compliance with quality standards, safety and mandatory compliance with Russian and recognized international ISO and HACCP regulations.

Fresh chilled meat of broiler chickens is delivered around Saint Petersburg the same day.